In the dynamic landscape of manufacturing, smart factories are fast becoming the standard for modern production. These intelligent environments leverage automation, optimize efficiencies, and cut costs while delivering top-notch products. Central to this transformation is the integration of Real-Time Location Systems (RTLS), a technology that is not just complementary, but foundational to the smart factory concept.

By 2030, ABI Research forecasts that RTLS services will generate an impressive $24.9 billion in revenue, underscoring their indispensable role in the industrial sector. In this article, we'll examine the key trends shaping smart manufacturing and intralogistics in 2024 and how Inpixon RTLS is driving this change by enhancing resource tracking and management in smart factories.

Key Topics

1. Expansion of Artificial Intelligence (AI) and Machine Learning (ML)

As we delve into smart factories and intralogistics in 2024, two pivotal studies accentuate the transformative potential of AI and ML.

Accenture's report underscores the potential for businesses to increase profitability by an average of 38% by 2035 through effective application of artificial intelligence (AI), contributing to a remarkable US$14 trillion boost in gross value added (GVA) across 16 industries and 12 economies. Key sectors such as information and communication, manufacturing, and financial services are expected to lead with the highest annual GVA growth rates, resulting in an additional US$6 trillion by 2035. Notably, the manufacturing industry shows a 39% increase in profit share between the base year 2035 and AI Steady-State 2035, showcasing AI's substantial impact on sector profits, as highlighted in the Accenture report.

Recognizing this pivotal role, business leaders view AI as crucial for success in the next five years, with 94% of respondents affirming its significance, according to the Deloitte State of AI in the Enterprise, 5th edition report.

These findings underscore the of AI and ML, among others, in manufacturing, aligning with our observations in the realm of smart factories. The potential benefits include:

- Productivity: AI and ML can automate tasks, optimize processes, and enhance resource allocation.

- Quality: These technologies can identify and prevent defects, ensure product consistency, and elevate overall quality.

- Flexibility: AI and ML enable adaptability in manufacturing processes, responding to changing market conditions and demand.

- Sustainability: These technologies contribute to reducing waste, improving energy efficiency, and minimizing the environmental impact of manufacturing.

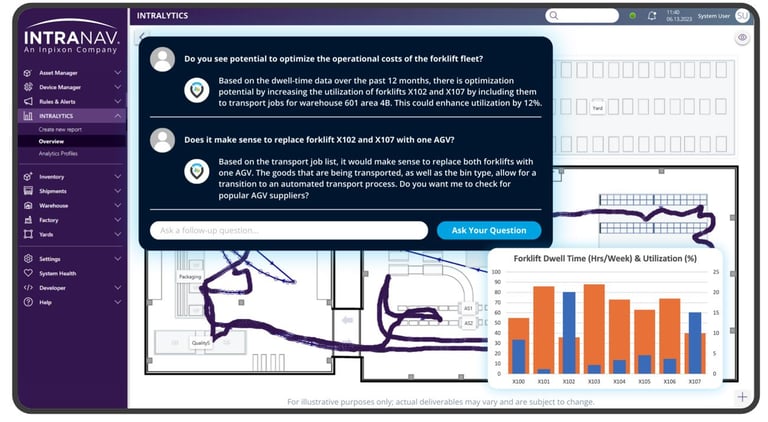

In the context of real-time location system (RTLS), our industrial RTLS platform represents a step forward, integrating ChatGPT for industrial analytics. AI, powered by natural language processing, revolutionizes data analytics, allowing users to engage in dialogues for interaction with complex data patterns, thereby enhancing the accessibility and user-friendliness of the analysis process. The system's generative AI capabilities delve deep into data relationships, facilitating better decision-making and unveiling hidden insights.

Crucially, the real-time analysis of data empowers smart factories to swiftly respond to operational changes and proactively suggest process improvements. This fusion of AI, machine learning, and RTLS not only propels the evolution of smart factories but also signifies a significant leap towards a future where manufacturing processes are not merely automated but intelligently orchestrated.

2. Service Models Redefine Supply Chain Dynamics

The progressive shift of supply chain processes towards supply chain as a service (SCaaS) and fourth-party logistics (4PL) signifies a fundamental change in how companies structure their logistical operations. The rise of service models, particularly with an impressive CAGR of 26.8%, plays a pivotal role for real-time location system (RTLS) providers.

Inpixon stands as one of the pioneers, recognizing this trend and introducing the "Location as a Service" (LaaS) subscription model in 2023. With the RTLS service package, all aspects of precise asset tracking are covered – hardware, software, installation, support and more – ensuring this capability throughout the entire subscription duration. The advantage lies in the ability for businesses to scale RTLS according to their needs, without risks, leading to more efficient utilization and cost savings. Initial investments are significantly reduced, thereby improving overall cost efficiency.

The growing acceptance of such service models underscores the increasing necessity for companies to externalize specific aspects of their supply chains. Research experts emphasize the indispensability of this shift, as it not only enables seamless global electronic connectivity, increased productivity, and reduced costs but also provides a qualitatively superior service and greater flexibility. Companies not embarking on this path expose themselves to the risk of losing competitiveness and grappling with financial challenges. The ascent of service models, particularly incorporating Location as a Service, thus becomes a crucial factor in the digital transformation and reshaping of the supply chain landscape.

3. Breaking Down Silos: Industry Leaders Embrace Collaborative Network Platforms for Intralogistics and Production Optimization

In the context of breaking down silos, major corporations have recognized the inefficiencies of using multiple in-house systems, a vulnerability exposed even before the COVID-19 pandemic. The pandemic further exacerbated these weaknesses, resulting in inflated buffer stocks, impaired information flow, and substantial IT costs for interfaces, maintenance, and upgrades.

Responding to these challenges, industry leaders are proactively transitioning their intralogistics and production processes to collaborative network platforms, effectively overcoming these silos.

This trend aligns with the insights from PwC's "Connected and Autonomous Supply Chain Ecosystems 2025" report, envisioning the future of supply chains as interconnected and self-orchestrated ecosystems. Integration across internal functions and logistics stakeholders through a unified data network allows real-time data availability for optimized decision-making. Companies aiming to thrive in the evolving digital marketplace are encouraged to transform their supply chains by strengthening integration with value chain partners. The report emphasizes that over 50% of Digital Champions prioritize supply chain transparency for sustainability.

However, a divide is evident, as about half of companies are implementing Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and/or logistics marketplaces. Notably, Digital Novices lag significantly, with only 17% using WMS and 4% utilizing TMS or logistics marketplaces.

The Inpixon RTLS platform emerges as a key player in this transformative Industry 4.0 landscape, boasting standardized API interfaces and MQTT for seamless integration into existing ERP, MES, WMS, BI, and other systems. Its technology-agnostic data integration ensures compatibility with various RTLS hardware technologies and other data sources. Solutions connected through interfaces and messaging protocols, featuring an intelligent IT architecture, break down silos, fostering a collaborative work environment that optimizes data exchange within and between companies.

4. UWB-Based Collision Avoidance Systems for Forklifts

In 2024, the trend towards prioritizing safety measures continues in the field of intralogistics. Recognizing the need to enhance the safety of their employees and facilities, companies are taking decisive actions.

Forklift accidents, identified by the US Occupational Safety and Health Administration (OSHA) as the primary cause of fatal injuries in warehouses and factories, resulted in 87 reported deaths in the United States in 2022. Annually, an estimated 35,000 to 62,000 injuries are linked to forklifts. Responding to these concerning figures, companies are increasingly investing in forklift safety technologies, placing emphasis on collision avoidance systems. With 11% of forklifts involved in accidents each year and a total of 855,900 forklifts (Industrial Truck Association) in the US, there is a growing recognition of the need for enhanced safety measures in the use of these industrial vehicles.

The future outlook for these technologies is promising:

- The demand for forklift tracking systems and collision avoidance is expected to continue rising in the coming years.

- Costs associated with these systems will decrease, making them more affordable for a broader range of businesses.

- Technology will further evolve, enhancing reliability and precision.

A study from the University of Michigan, Ann Arbor, affirms this trend. In a facility with 50 forklifts, the implementation of UWB-based collision avoidance systems achieved a 60% reduction in collisions. This led to a 10% decrease in operating costs and a 20% improvement in safety.

The most common sensor types for collision avoidance systems include radar sensors, ultrasonic sensors, and camera sensors, sometimes in combination. However, time-of-flight UWB RTLS is on the rise due to the technology’s range, accuracy and low latency.

Two primary types of collision avoidance systems are warning systems (e.g., lights, sounds, etc.) and intervention systems (e.g., to activate the forklift brakes, etc.), with the latter providing higher protection but also incurring higher costs.

The selection of the appropriate system depends on various factors, including the work environment, safety requirements, and the company's budget. UWB-based systems stand out for their range, enabling distance detection of up to 50 meters. In comparison to other systems limited to 10 to 20 meters, this offers early obstacle detection, effectively preventing collisions.

The advantages of UWB-based collision avoidance systems extend to improved safety, increased productivity, and higher efficiency. They prove particularly beneficial in environments with high radio frequency traffic, as they are not susceptible to interference from other radio signals.

In summary, UWB-based collision avoidance systems for forklifts provide a comprehensive solution, elevating safety standards while contributing to a more efficient intralogistics operation.

5. The Pervasive Integration of Sensors and Connected Devices

The increasing integration of sensors and connected devices in manufacturing is a significant trend for 2024. These technologies play a crucial role in capturing data from machine operations to product quality and process efficiency, leading to optimized production, improved quality, and reduced maintenance costs.

According to the "Digital Factories 2020" report by PwC, connecting factories internally and externally through an integrated Manufacturing Execution System (MES) is crucial. Currently, 29% of respondents state that their companies have implemented networking technologies linking components, machines, production management, transportation vehicles, workers, and products. However, more than twice as many (60%) anticipate doing so by 2022. Typically, connectivity involves sensors reading data from RFID chips and transmitting it to data platforms. A similar percentage of respondents (64%) report having already implemented such sensor networks and connected data platforms or plan to do so.Source: https://www.pwc.de/de/digitale-transformation/digital-factories-2020-shaping-the-future-of-manufacturing.pdf P. 26

Especially in machine monitoring, sensors enable the early detection of wear or damage, allowing for preventive maintenance measures and minimizing downtime.

The positive return on investment (ROI) for manufacturing sensors is strengthened by decreasing costs and enhanced data collection and analysis.

Real-time location systems (RTLS) play a central role by enabling real-time object localization through RF, ultrasound, or optical technologies. The integration offers benefits such as improved visibility, process optimization, and early issue detection, thereby reducing downtime.

Highlighting this trend:

- Mordor Intelligence: The Real-Time Location System (RTLS) Market size is estimated to be USD 5.73 billion in 2024 and is expected to reach USD 17.19 billion by 2029.

While integration is not new, current developments are amplifying:

- Increasing availability at lower costs makes technologies more accessible.

- Improved data collection and analysis facilitate insights and process improvements.

- New applications expand potential advantages.

New developments include:

- Sensors with real-time data capture for quicker issue resolution.

- Self-learning sensors recognizing patterns and enhancing performance.

- AI-powered sensors analyzing data for business-relevant insights.

These advancements will drive the integration of sensors and connected devices in manufacturing, fundamentally altering the industry by enhancing productivity, quality, and efficiency.

6. Versatile Solutions in a Single Device: 3-in-1 Location-Aware Technology

A prominent trend in the field of location-aware technology is the integration of 3-in-1 functionalities in a single device, catering to multiple use cases. This cutting-edge technology encompasses:

- TDoA real-time location tracking: Applying the time difference of arrival (TDoA) method, this feature enables precise real-time location tracking.

- ToF two-way ranging (SDS-TWR): The time-of-flight (ToF) technology allows for accurate distance measurements using signals, proving particularly useful in scenarios with bidirectional ranging.

- Bidirectional wireless communication: The integration of bidirectional wireless communication facilitates seamless data communication and interaction between devices, opening possibilities for enhanced connectivity.

This trend enables the development of scalable real-time solutions capable of tracking thousands of tags simultaneously. Additionally, the technology expedites software and application development through a user-friendly API, eliminating the need for additional RF design or firmware implementation. This optimization significantly contributes to the rapid deployment and innovation of location-aware applications.

Another trend on our radar: Software Driven Facilities: The Future of Factories, Warehouses & Supply Chains

The Inpixon Advantage: Transforming Smart Factories with Intelligent Location Solutions

Inpixon's Indoor Location Services can enhance smart factories' productivity and efficiency on multiple levels. By leveraging Inpixon's indoor intelligence solutions, manufacturers & intralogistics experts can:

- Maintain inventory management accurately and efficiently, reducing time and labor costs.

- Monitor real-time asset movement, ensuring the optimal use of resources and equipment.

- Improve worker safety with geofencing and instant alerts in hazardous environments.

- Enhance worker productivity by monitoring workflow and identifying areas for improvement.

- Access data analytics for insightful decision-making, long-term strategy, and operational optimization

Are you interested in learning more about the innovations underway in smart factories? Connect with an expert at Inpixon to get started.

-3.png?length=1000&name=Inpixon%20LinkedIn%20Banner%20August%202025%20(2)-3.png)