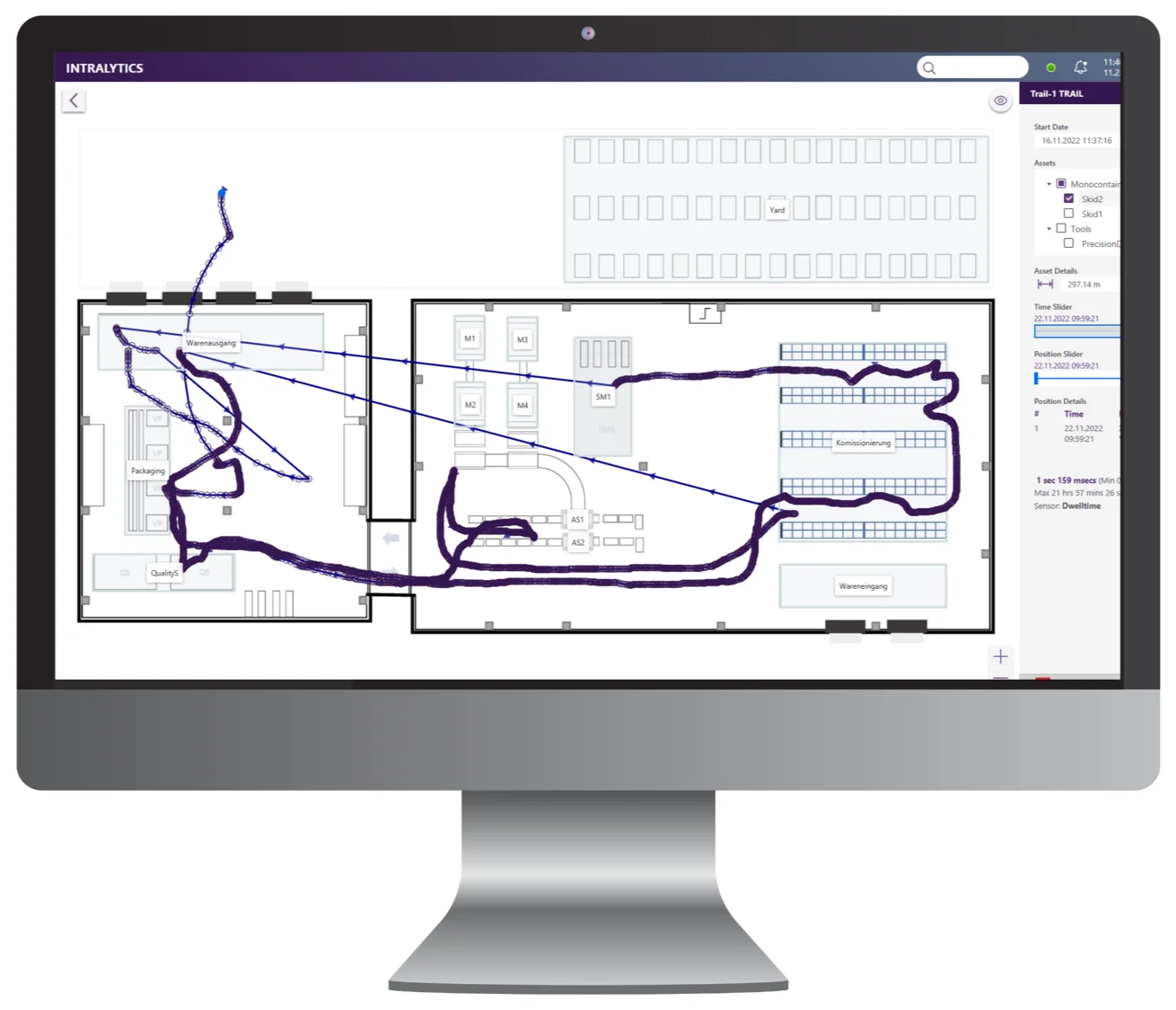

Real-time tracking of forklifts and other vehicles, like tugger trains and hand pallet trucks, is vital for enhancing logistics and production efficiency. Inpixon's forklift tracking solution ensures precise location accuracy, reaching up to +/- 40 cm with UWB RTLS technology. This boosts visibility, efficiency, and profitability and enhances workplace safety.

The solution facilitates comprehensive process tracking, offering a holistic overview of vehicle positions in the warehouse, factory, or yard. Easily integrate real-time location data into EWM, ERP, MES, and other systems. Further replace manual workflows with smart IIoT and RTLS technology, including vehicle auto-ID and automatic process triggering.

Our UWB-based collision avoidance system provides advanced warnings, and offers optional automatic braking, along with setting and enforcing speed limits within controlled areas.

Additionally, achieve faster throughput through rack-level guiding. This approach empowers logistics and production managers to optimize fleet resources, reduce man-hours wastage, and proactively prevent accidents.

-3.png?length=1000&name=Inpixon%20LinkedIn%20Banner%20August%202025%20(2)-3.png)

-2.png?width=1200&height=1200&name=Design%20ohne%20Titel%20(2)-2.png)

.png?width=500&height=540&name=Mask%20group%20(2).png)

-1.png?width=155&height=96&name=Mask%20group%20(4)-1.png)