Inpixon RTLS Platform:

Real-Time Tracking Meets Predictive AI

Transform live location data and shop floor signals into autonomous workflows. Inpixon bridges the gap between your physical operations and your ERP/MES/WMS to eliminate delays, improve on-time delivery, and maximize throughput.

Three Steps to an Intelligent Shop Floor

1

Capture

Live location, Auto-ID, and shop floor signals create complete operational visibility.

Track assets, WIP, equipment, and vehicles to cut search time, handoffs.

2

Automate

Customizable rules trigger workflows and post updates across ERP, MES, and WMS in real time.

Hands-free execution, fewer manual handoffs.

3

Optimize

Industrial AI spots bottlenecks and risks, identifies root causes and recommends next steps.

Protect on-time delivery by addressing issues early.

Inpixon RTLS Platform Stack

Real-Time Location & Digital Twin

- Live Tracking: Monitor assets, vehicles, WIP, and people across the facility.

- Dynamic Mapping: Digital twin with zones, dwell times, utilization and movement history.

- Technology-Agnostic: Seamlessly integrates UWB, BLE, Chirp, GPS, RFID, NFC, QR, Wi-Fi, LiDAR, and more.

Automated Execution (ERP, MES, WMS)

- Event Triggers: Turns location and Auto-ID events into automated process steps, validations, and task handoffs.

- System Sync: Posts transactions and status updates directly into ERP, MES, and WMS.

- Eliminate Gaps: Reduces manual scanning, coordination effort, and process gaps across shifts and sites.

Safety & Issue Resolution

- Instant Detection: Spot delays, deviations, and hazards on a live map.

- Proactive Alerts: Immediate warnings for restricted zones, missed steps, near-collisions and process interruptions.

- Rapid Root-Cause: Resolve issues faster with timelines, zone dwell insights, and movement replay.

Agentic AI & Analytics

- Predictive Foresight: Industrial AI identifies risks early, explains root causes, and recommends the next best action.

- Deep Insights: Advanced analytics: heatmaps, trails, dwell times, utilization, cycle-time views, and trends.

- askPixi: Conversational interface to query live operations and enterprise data in plain language.

Modular Intelligence for Every Workflow

Module — Warehouse

Automated Execution & Error-Proofing

Hands-Free Execution: Accelerate goods receipt and issue events without manual barcode scanning. Transactions are recorded instantly in WMS and ERP systems, automatically triggering and assigning transport orders to your fleet.

24/7 Digital Twin Guidance: Our Digital Twin replicates physical processes to give immediate guidance. By combining Auto-ID, X,Y,Z positioning, and load detection, the system verifies every step in real time.

Closed-Loop Feedback: Eliminate wrong picks and misplacements with sensory-based status detection. This closed-loop system maintains continuous visibility across forklifts and inventory to ensure a seamless, error-free process flow.

Key Benefits

Reduces flow interruptions and idle time, helping the warehouse maintain stable daily output without adding resources.

Minimizes manual routines and coordination effort so staff can focus on productive work instead of searching, validating or correcting tasks.

Prevents misplacements, replenishment issues and stock-related delays, improving service levels and reducing costly workflow disruptions.

Factory — Process Flow

Real-Time Bottleneck Detection & Optimization

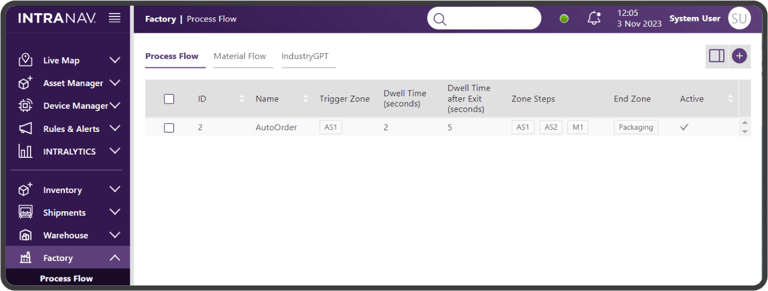

Automated Time Stamping: Record and monitor production workflows using precise timestamps and geozones. The system automatically captures every process step, eliminating manual documentation and identifying idle times instantly.

Structured Process Mapping: Gain a digital representation of your entire production cycle. By mapping actions and dependencies, the system highlights bottlenecks, allowing for immediate intervention to maintain a steady flow.

Proactive Production Control: Transform transparency into action. The module enables proactive measures based on real-time data, ensuring a seamless and efficient production cycle from start to finish.

Key Benefits

Gives teams the clarity to run production with fewer surprises, less firefighting and more consistency from shift to shift.

Helps catch delays or inefficiencies early, reducing the likelihood of line stops or cascading disruptions.

Strengthens coordination across stations, lowering the operational noise that slows cycle times and increases variability.

Factory — Material Flow

Dynamic Transport & Cycle Time Optimization

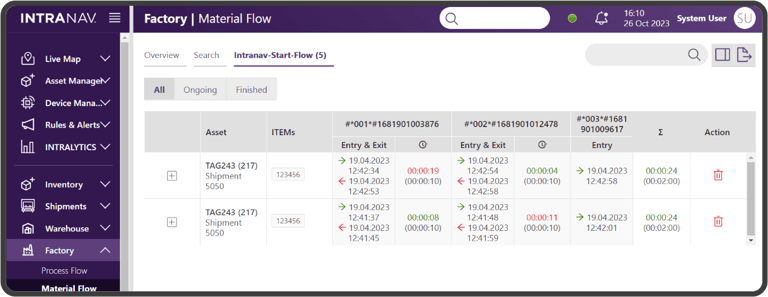

Real-Time Movement Capture: Track material entry and exit points across the shopfloor with second-level accuracy. This automates the recording of transport flows and material locations, replacing manual tracking with live data.

Automatic Dwell Time Calculation: Reveal exactly where queues form and which process steps hinder your flow. By automating these calculations, the system identifies inefficiencies without the need for manual time-studies.

Data-Driven Bottleneck Pinpointing: Use the "End Status" feature to define total cycle times based on a factual dataset. This allows managers to optimize workflows and eliminate bottlenecks with precision to maintain peak production speed.

Key Benefits

Highlights exactly where material flow slows down so teams can improve speed and predictability without overstaffing.

Enables teams to respond earlier to issues that would otherwise cause delays, urgent re-routing or schedule changes.

Reduces wasted movements, unnecessary routes and excess safety buffers that tie up working capital.

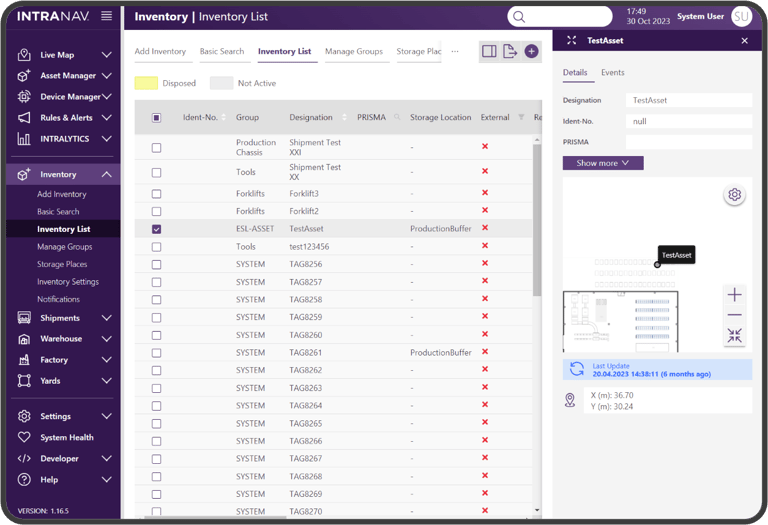

Module — Equipment Manager

Automated Asset Tracking & Movement Control

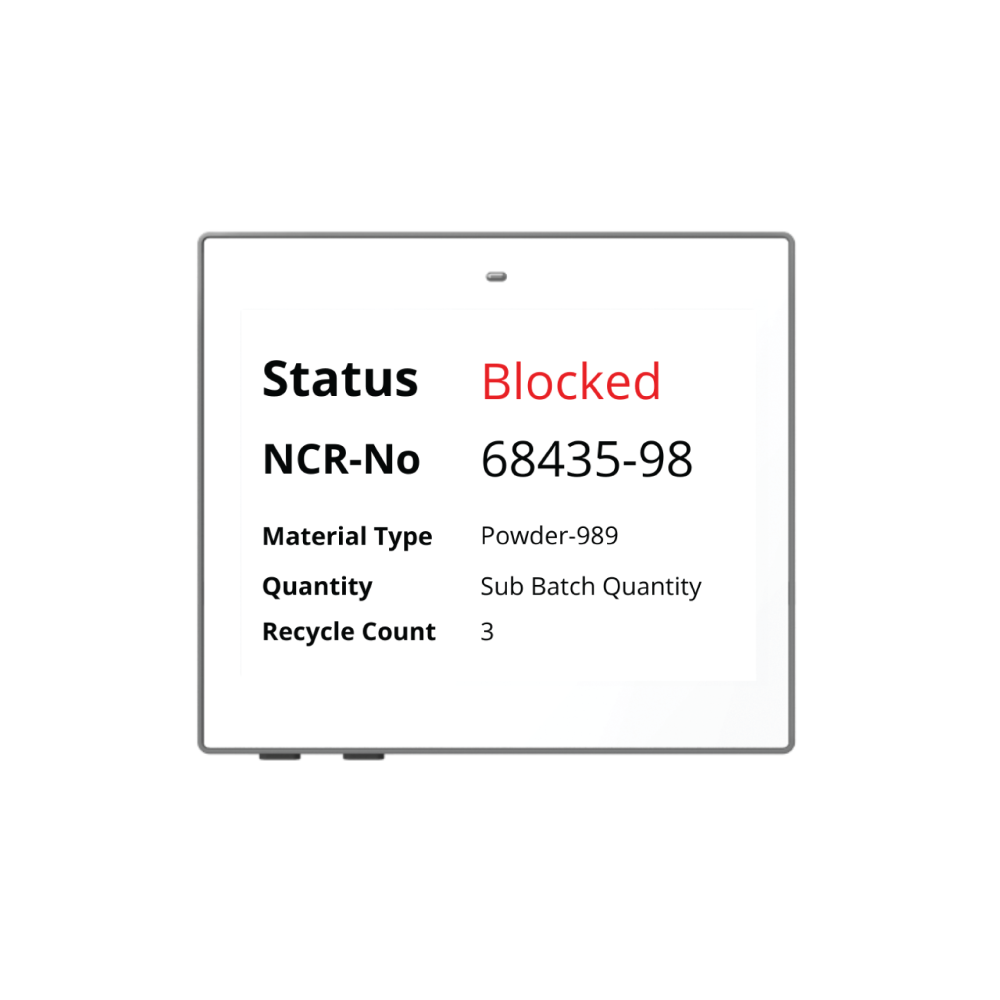

Eliminate Manual Searches: Provide real-time localization for tools, carriers, and components to ensure every asset is exactly where it needs to be. The Inventory Archiving & Capture System automates the integration of new objects for seamless scaling.

Digital Twin Management: Map location data into a live "Digital Twin" to manage object groups through advanced search and filter functions. This centralized visibility significantly increases operational speed by coordinating asset movements facility-wide.

Proactive Zone-Based Alerts: Trigger automated notifications for unauthorized movements or process deviations based on specific geozones. These triggers integrate with third-party systems to handle errors instantly and maintain strict process compliance.

Key Benefits

Reduces non-productive search time and keeps workflows moving smoothly across shifts and departments.

Prevents losses, mix-ups and delays caused by missing or misplaced equipment.

Ensures issues are detected early and handled before they interrupt production or create unnecessary costs.

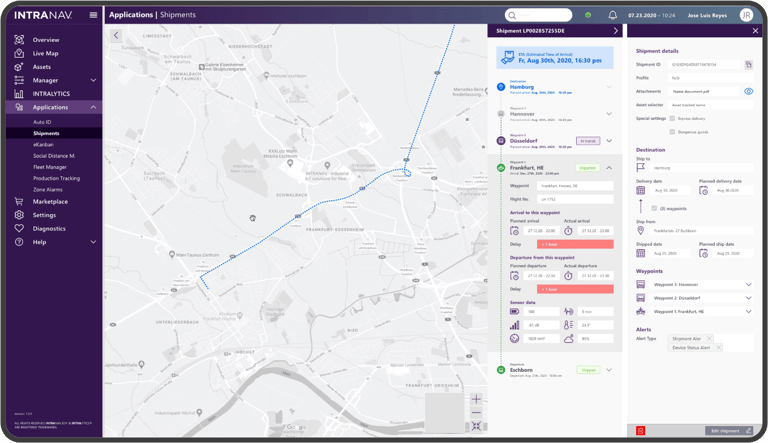

Module — Shipments

Global Supply Chain Visibility & Real-Time Logistics Control

Dynamic Cargo Digital Twin: Create a digital representation of cargo and shipments to track all destinations and planned stops. The system automatically calculates accurate ETAs based on real-time external data, centralizing delivery IDs and provider management.

Active Monitoring & Delay Response: Integrate GPS and third-party devices to monitor shipment statuses across the global supply chain. The live dashboard enables teams to respond instantly to delays, ensuring a smooth flow of goods through automated tracking.

Proactive Condition Alerts: Trigger customizable notifications for deviations in shipment conditions, specifically designed for sensitive goods. The system provides a detailed tracking history to automate in-depth analysis and long-term process optimization.

Key Benefits

Improves planning accuracy and reduces delays that negatively impact downstream operations.

Enables proactive handling of deviations instead of reacting when it's already too late.

Combines performance indicators into a single view, helping teams negotiate better and avoid costly inefficiencies.

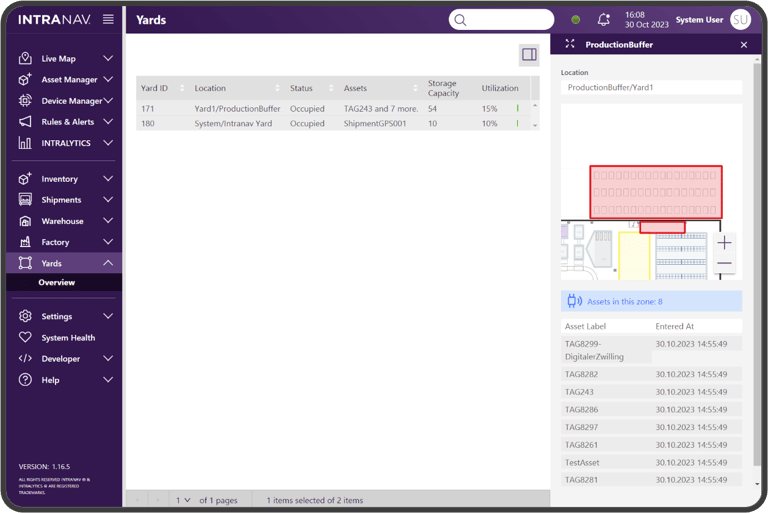

Module — Yard

Yard & Storage: Synchronized Outdoor Asset & Dock Management

Active Workflow Direction: Automate operations across outdoor storage and truck yards to eliminate idle times and manual search efforts. Real-time occupancy monitoring actively directs delivery and storage workflows, using automated alerts to ensure fluid vehicle movements.

Intelligent Slot Assignment: Optimize capacity for factory storage and truck docks via GPS or RTLS integration. This precision mapping enables the intelligent assignment of parking and storage slots, ensuring every asset is instantly locatable and maximizing the utilization of all outdoor areas.

Synchronized Transport Schedules: Accelerate turnaround times by centralizing movement data and synchronizing available space with transport schedules. These proactive workflows ensure a seamless transition from arrival to storage, significantly increasing total throughput.

Key Benefits

Reduces waiting times and accelerates vehicle and material flow across loading and buffer zones.

Prevents operational slowdowns before they affect transportation schedules or dock availability.

Improves allocation, reduces congestion and helps avoid unnecessary costs from under- or over-utilization.

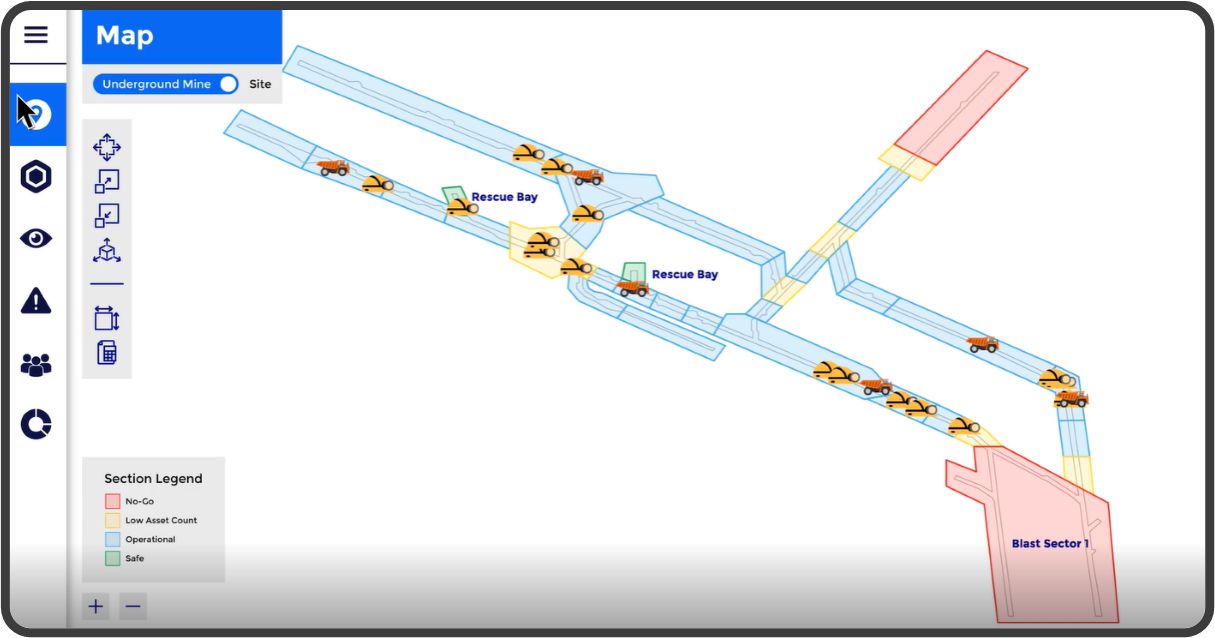

Module — Smart Mine 4.0

Smart Mine 4.0: Autonomous Safety & Workflow Efficiency

Reliable Safety & Search Elimination: Trigger automated collision avoidance and personnel safety protocols using robust location data. Geofencing and zone alerts eliminate manual monitoring by instantly flagging unauthorized entry into hazardous areas and ensuring all personnel are accounted for.

Automated Traffic & Maintenance Triggers: Streamline underground logistics with automated traffic control and route optimization to eliminate bottlenecks. The system detects equipment failures or idling based on movement patterns, triggering proactive maintenance workflows to minimize downtime.

Data-Driven Remote Operations: Transform position data into heatmap analytics for remote operations and strategic productivity planning. This enables coordinated, compliant workflows across the entire site and ensures operational excellence without manual reporting.

Key Benefits

Reduces the likelihood of accidents by ensuring teams can act before dangerous situations escalate.

Minimizes downtime caused by unclear movements, access issues or undetected operational deviations.

Ensures safety regulations, access rules and procedures are followed consistently without extra manual effort.

Proven Warehouse Efficiency Results

Our Smart Warehouse solution with RFID and UWB technology delivers measurable improvements in overall logistics operations.

Increased efficiency and productivity

across all warehouse processes, from goods identification to storage and retrieval operations.

Elimination

of RFID scanning

processes

Real-Time

optimization of transport orders to the fleet

Reduced

processing time and

improved throughput

Optimization

of route and capacity utilization with storage transparency

One Platform Delivers Everything You Need

FAQs

-

What kind of problems does the Inpixon RTLS platform solve that ERP, MES or WMS alone cannot?

It connects physical movements with digital processes in real time. That means you see where assets, materials and vehicles actually are, not only what systems think they are. This closes gaps between planning and reality, reduces manual corrections and enables true location-based automation. -

Can we start with one use case or area and expand later?

Yes. Many customers start with a single use case or zone, such as warehouse, yard or a production line, and scale step by step. The platform is designed for modular rollouts across additional sites, halls or processes.

-

What is the difference between Location as a Service (LaaS) and a traditional purchase?

LaaS bundles hardware, software, mapping, installation, maintenance and support into a recurring fee. A traditional model separates hardware purchase and software licensing. LaaS reduces upfront investment and simplifies budgeting, while a traditional purchase suits customers who prefer CAPEX.

-

How much effort is required from our internal teams during deployment?

Inpixon handles site assessment, design, installation, calibration and initial configuration. Your teams mainly provide process know-how, system access for integrations and key users for testing and training.

-

What happens if the RTLS or network connection is temporarily unavailable?

The system is designed for robust operation with buffering and failover mechanisms where applicable. When connectivity is restored, buffered events are synchronized. Critical automations can be configured with safe defaults or manual override procedures.

-

How does the platform handle data security and ownership?

All operational data remains under your ownership. Data is encrypted in transit and at rest, and access is controlled via roles and permissions. The platform follows established best practices for authentication, network segmentation and data governance.

-

How quickly can we expect to see measurable results?

Most customers see tangible improvements in search times, throughput or on-time performance within weeks after go-live in a first area. Full ROI depends on scope and use case, but is typically achieved within months rather than years.

-

What level of support can we expect after go-live?

Inpixon provides ongoing monitoring, maintenance and support. This includes system updates, troubleshooting, assistance with new use cases and, in LaaS engagements, proactive performance reviews of coverage and accuracy.

-

Is the platform available on-premise, in the cloud or at the edge?

Yes. The platform supports all three deployment models. You can run it fully on-premise for environments with strict IT or security requirements, deploy it in the cloud for easier scaling, or use an edge setup to keep latency low and maintain operations even if cloud connectivity is interrupted.

-

How do I know which deployment model is right for my facility?

On-premise is ideal when strict data control or offline capability is required. Cloud works best for multi-site scalability and easy maintenance. Edge is recommended when real-time performance is critical but data should stay local. Many customers use a hybrid setup combining cloud dashboards with local edge processing.

-3.png?length=1000&name=Inpixon%20LinkedIn%20Banner%20August%202025%20(2)-3.png)