In today's fast-paced manufacturing landscape, understanding and optimizing production processes in real-time is essential for staying competitive. Our Smart Factory module offers a comprehensive solution, leveraging precise time stamps and zone tracking to monitor workflows with unparalleled accuracy.

By providing a structured representation of production processes, our system enables proactive intervention to address bottlenecks and idle times swiftly. This increased transparency across all production activities allows for a seamless and efficient production cycle.

Utilizing a structured, rule-based approach to process management, our platform ensures precise monitoring and optimization of material movements. With a detailed and transparent view of production processes, businesses can enhance their understanding and awareness of operational sequences, enabling them to pinpoint workflow bottlenecks for proactive issue resolution.

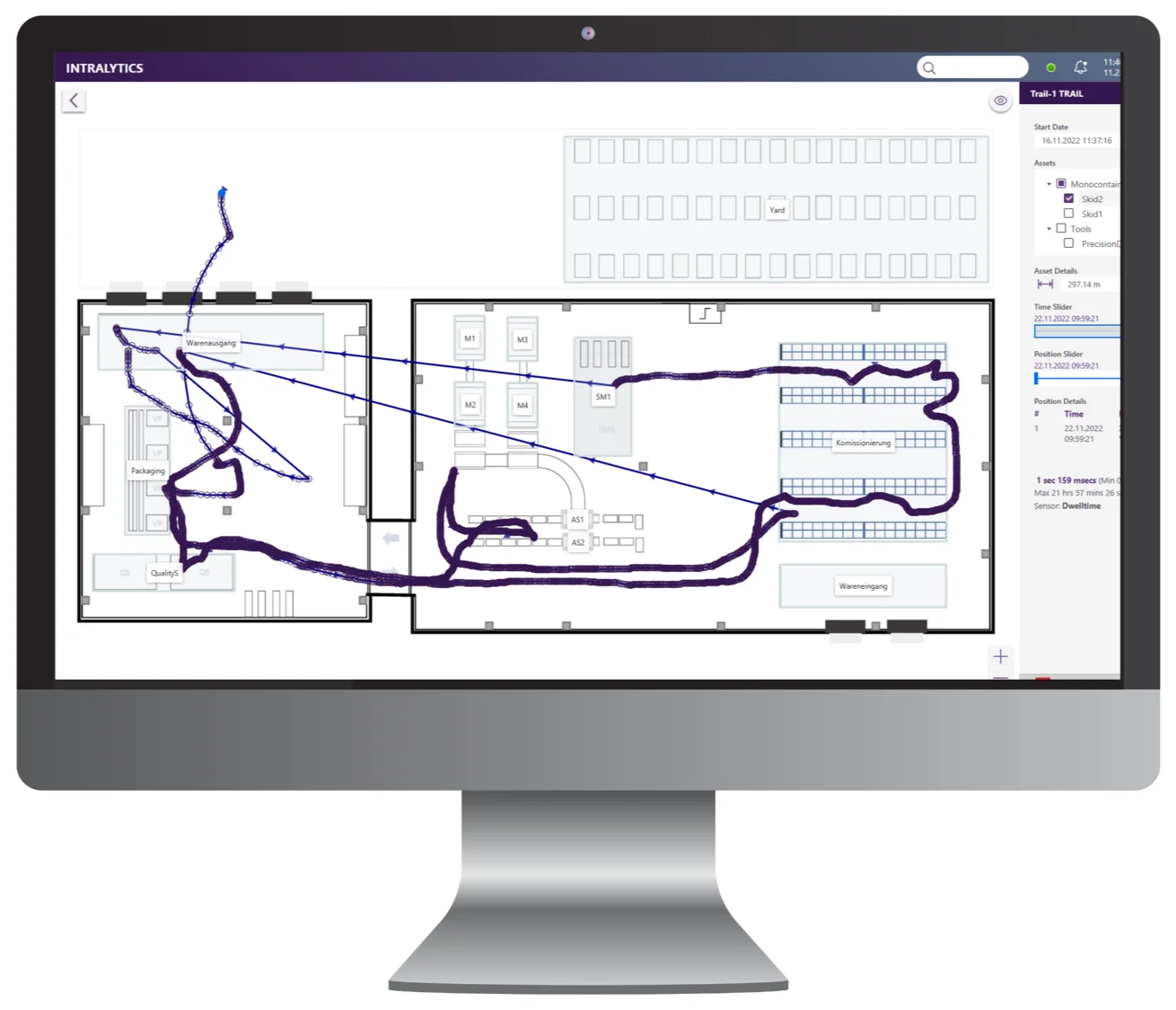

Through advanced analysis tools such as Heatmaps, Trails, and Zone Dwell Time Analysis, we offer in-depth insights into temporal frequencies, asset movements, and zone performance. These tools empower businesses to identify congestion points, optimize layouts, and allocate resources effectively, ultimately reducing delays and achieving significant time savings throughout the entire production lifecycle.

With Real-Time manufacturing analytics, you can revolutionize your manufacturing operations, streamline workflows, and drive efficiency like never before.

-3.png?length=1000&name=Inpixon%20LinkedIn%20Banner%20August%202025%20(2)-3.png)

-MANUANALY-Inline-Image-1.png?height=2000&name=(NEW)-MANUANALY-Inline-Image-1.png)